What Is an Imaging Colorimeter? Applications & Features

Introduction

What is imaging colorimeter?

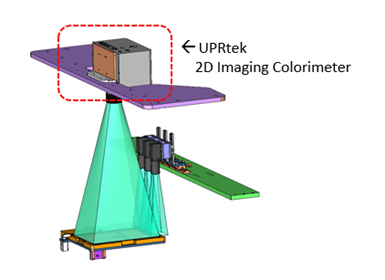

Regarding Imaging Colorimeter Principle, an imaging colorimeter, such as the UPRtek Imaging Colorimeter, is a specialised optical device that combines a high-resolution camera with precise photometric filters (XYZ Filter) to measure spatial luminance and color distributions across an image according to every pixel of camera sensor. The device captures detailed data for every pixel, making it ideal for evaluating the uniformity, brightness, and color consistency of displays, LEDs, and lighting systems.

How accurate is imaging colorimeter?

By employing multi-point calibration with a spectroradiometer, an imaging colorimeter can address the issues related to the field of view of the camera and enhance the flat-field uniformity to duplicate equivalent of precisio of a spectroradiomter upon spatial lumiance and color distribution.

- What is imaging colorimeter?

- How accurate is imaging colorimeter?

- What is an imaging colorimeter used for?

- How to use an imaging colorimeter?

- What is the difference between an Imaging colorimeter and a spectroradiometer

- Characteristics of UPRtek’s Imaging Colorimeter

- FAQ of an Imaging Colorimeter

- Challenge of Imaging Colorimeter

What is an imaging colorimeter used for?

It measures multiple points simultaneously, making it suitable for assessing uniformity, defects, and color consistency in displays or large lighting systems. An imaging colorimeter performs better in terms of measuring efficiency and measuring speed.

Imaging colorimeters are widely used in:

Display Testing:

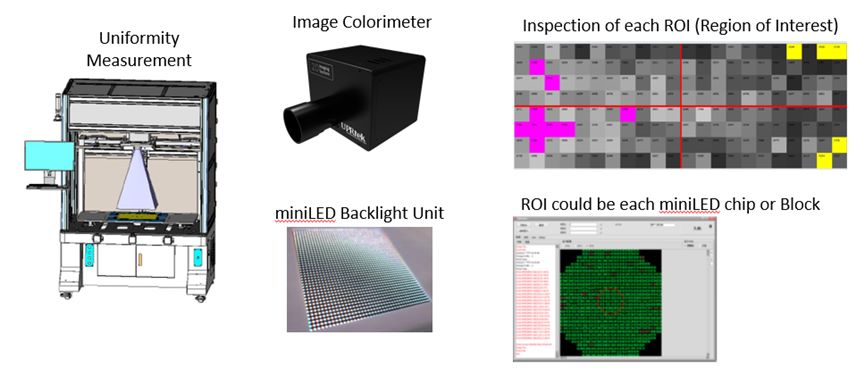

For technologies like LCD, OLED, miniLED, and microLED, evaluating luminance, uniformity, and color consistency.

Lighting Systems:

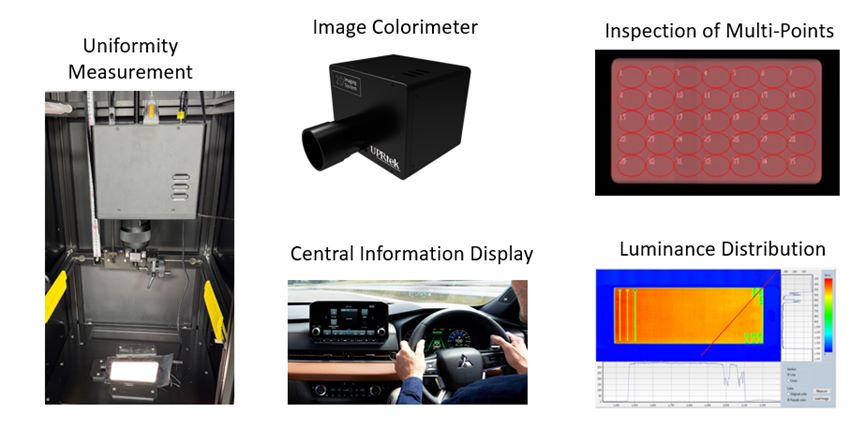

Assessing LEDs, automotive lighting, and digital signage for brightness and color distribution.

Quality Control:

Ensuring uniformity and identifying defects in production lines.

Optical Inspection:

Analyzing virtual imaging systems (e.g., AR glasses) and small-scale devices like microLED displays.

Automotive Display & Smart cockpit:

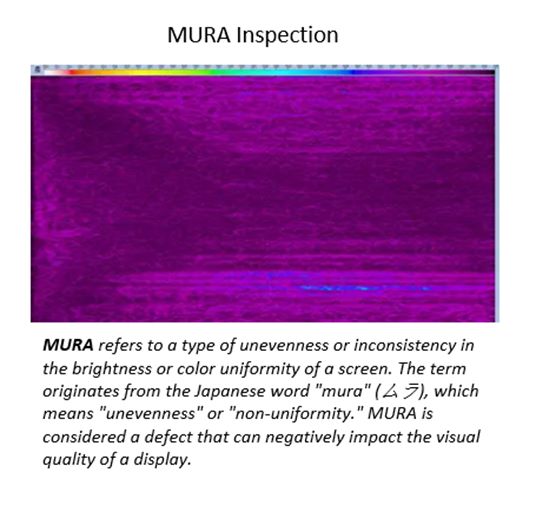

Testing of Uniformity, MURA, and BlackMura for automotive display optical measurement.

How to use an imaging colorimeter?

Preparation

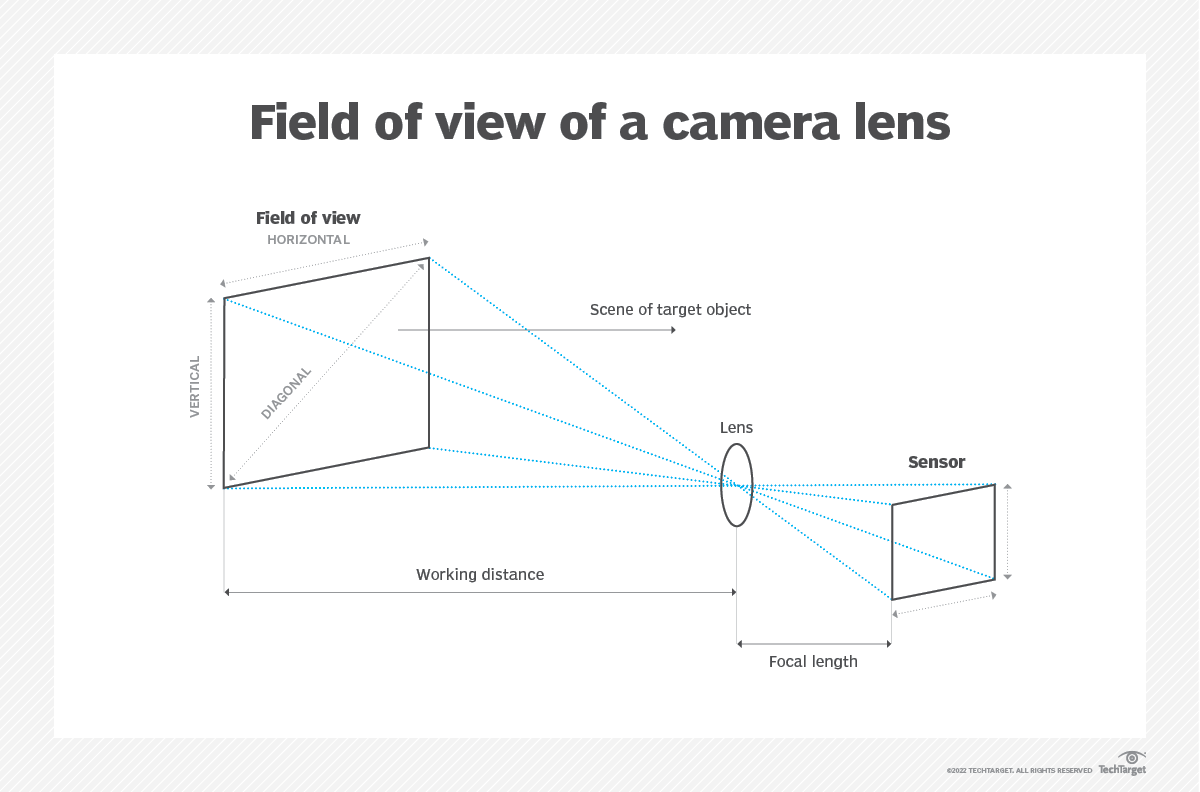

Including set up the environment, testing pattern, suitable aging of DUT (such as Display), position the imaging colorimeter, working distance for suitable FOV (Field of View) that match the dimension of DUT.

Calibration:

- Device Calibration: Calibrate the imaging colorimeter using a reference spectroradiometer or standard light source.

- Follow the manufacturer’s instructions for calibration procedures, ensuring luminance and chromaticity accuracy.

- Focus Adjustment: Adjust the focus of the colorimeter’s lens so that the display pixels or test patterns are sharp and clear. In addition, use the software’s live view to confirm proper focus.

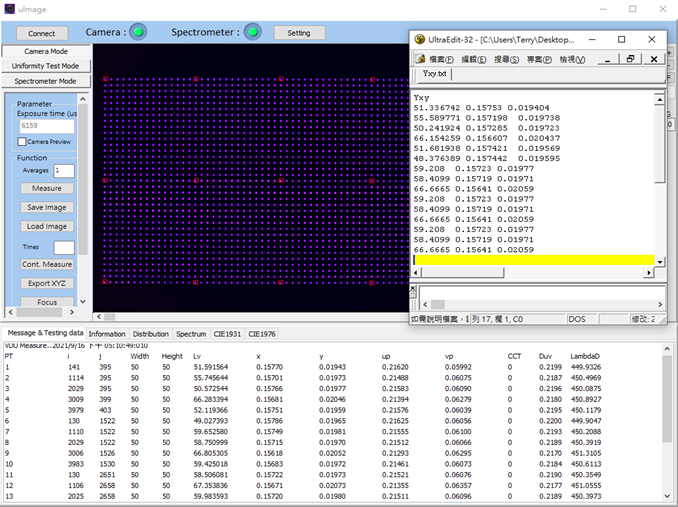

Perform Measurement:

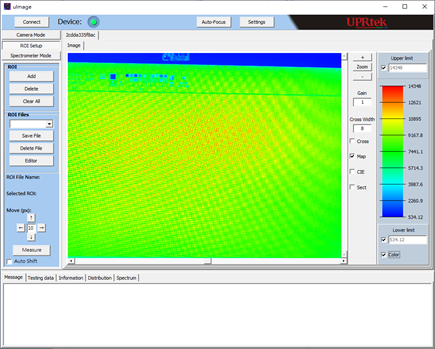

- Set up ROI (Region of Interest)

- Uniformity Measurement

- MURA Measurement

- Gamma and Contrast Testing

- Color Accuracy Testing

Analyze Data:

- Generate Reports (Luminance uniformity maps, ChromaticityMURA defect severity and locations, etc)

- Export Results (e.g., CSV, PDF, or images)

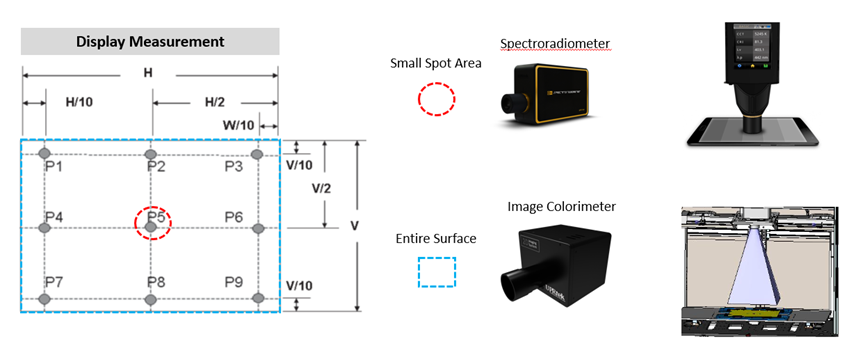

What is the difference between an Imaging colorimeter and a spectroradiometer

Spectroradiometer

Measures light at a single point with high spectral accuracy, suitable for research and calibration.

Imaging Colorimeter

Measures spatial properties across entire images, making it more efficient for evaluating uniformity, defects, and large areas.

The UPRtek MA Series Imaging Colorimeters represent cutting-edge imaging colorimeter technology, offering a balance of speed, precision, and versatility tailored for production and research environments.

Characteristics of UPRtek’s Imaging Colorimeter

- Advanced Algorithms:

We use computational methods to analyze data from optical sensing, offering features like auto-focusing, MURA (non-uniformity) analysis, and region-of-interest (ROI) measurements. - Spatial Light and Color Measurement:

Imaging colorimeters capture data for every pixel in an image, allowing for detailed analysis of luminance, color uniformity, and brightness distribution. - High-Precision Calibration:

Refers to spectroradiometers as reference tools for calibrating photometric filters and ensuring accuracy in measurements. We also use our algorithm to involve signal processing techniques to enhance measurement accuracy. - Dynamic Brightness Range:

Equipped with neutral density (ND) filters, imaging colorimeters can handle a wide range of brightness levels, from low to extremely high intensities. The 65MP specification supports up to 100 million cd/m2 for microLEDs and other ultra-high brightness measurements. - Fast and Efficient Analysis:

We develop algorithm and sensing technology to improve measurement time and data process time. Compared to other imaging colorimeters, the measurement time of UPRtek’s imaging colorimeter reaches 1~2 seconds, that is especially for high-throughput production environments.

FAQ of an Imaging Colorimeter

1. What can an imaging colorimeter measure?

- Luminance (brightness)

- Chromaticity (color coordinates, typically in CIE color spaces)

- Contrast ratio

- Gamma curves

- Display uniformity

- MURA defects (non-uniformity in displays)

2. Can an imaging colorimeter detect MURA?

Yes, imaging colorimeters are commonly used for MURA analysis in displays. They can identify and quantify defects like dark spots, brightness inconsistency, or color non-uniformity.

3. Can it be used for automotive displays and lighting?

Absolutely! Imaging colorimeters are often used to evaluate dashboard displays, HUDs (head-up displays), and ambient lighting in vehicles.

4. What factors should I consider when buying an imaging colorimeter?

- Measurement accuracy and speed

- Sensor resolution

- Supported display types including capability of handling dimming problem

- Software features and automation compatibility

- Cost and manufacturer support

Challenge of Imaging Colorimeter

Imaging colorimeters rely on cameras equipped with photometric filters to capture luminance and color data across a spatial area, but there are inherent challenges that necessitate calibration using a spectroradiometer. Here’s a detailed technical breakdown of why this calibration is critical:

1. Flat-Field Calibration and Uniformity

- Challenge:

Imaging colorimeters measure light intensity and color across the entire image sensor (e.g., a CMOS or CCD sensor). These sensors can exhibit non-uniform sensitivity across their surface, resulting in inaccuracies such as brightness and color gradients in the measured data. - Solution:

Calibration against a spectroradiometer ensures that the imaging colorimeter compensates for pixel-to-pixel variations in sensitivity, producing a “flat-field” response. This correction ensures uniform measurement across the entire field of view (FOV).

data source: techtarget

2. View Angle Dependency and Optical Aberrations

- Challenge:

Imaging colorimeters are subject to view angle errors because:- Camera optics (lenses) can introduce spatial distortions, chromatic aberrations, and vignetting effects (where the edges appear darker).

- Light entering the lens at oblique angles may not pass through filters and lenses uniformly, leading to color and luminance inaccuracies.

- Solution:

A spectroradiometer provides a precise single-point measurement at a reference angle, typically normal to the surface being measured. By comparing this to the imaging colorimeter’s measurements, corrections can be applied to account for view angle dependencies and optical distortions.

3. Spectral Mismatch of Filters

- Challenge:

Imaging colorimeters use RGB or XYZ filters to mimic the human eye’s response (CIE 1931 standard). However:- These filters are approximations and might not perfectly match the CIE color matching functions.

- Any deviation (spectral mismatch) introduces errors in color measurements, especially when measuring light sources with complex spectra like OLEDs or microLED.

- Solution:

A spectroradiometer directly measures the spectral power distribution of the light source. This data is used to calibrate the colorimeter’s filters, compensating for mismatch and ensuring accurate colorimetric values (e.g., CIE XYZ, u’v’, CCT).

4. Temporal and Spatial Calibration

- Challenge:

Imaging colorimeters can drift over time due to sensor aging, environmental conditions, or mechanical factors. Additionally, spatial non-linearities (e.g., differences in response across the FOV) can arise during production. - Solution:

Periodic recalibration using a spectroradiometer ensures that the imaging colorimeter remains traceable to a standard, maintaining accuracy over time. This also includes correcting linearity errors in response to brightness levels.

Summary of Why Calibration Is Essential

Imaging colorimeters use spatial data across thousands or millions of pixels, while spectroradiometers excel at single-point measurements with high spectral fidelity. By referencing spectroradiometer data:

- Flat-field calibration corrects non-uniformity across the image sensor.

- View angle corrections mitigate errors from camera optics.

- Spectral calibration compensates for filter mismatches.

- Traceability and accuracy are maintained over time, ensuring reliability in diverse applications.

This complementary relationship allows imaging colorimeters to deliver fast, spatially resolved measurements while maintaining the high accuracy associated with spectroradiometers.

Conclusion

The UPRtek Imaging Colorimeter, is a highly versatile instrument that is widely used in quality control, display testing, and production environments. Its advanced capabilities make it the clear choice for professionals who need to evaluate complex visual and lighting systems efficiently and at high speed. Unlike single-point measurement tools, imaging colorimeters analyse entire surfaces in one capture, making them the most effective solution for high-throughput evaluations.

We developed computational methods to analyze data obtained from optical sensing, and it involves signal processing techniques to enhance measurement accuracy.

UPRtek’s Imaging colorimeters offer a range of solutions for different resolutions, including the MA120S/MA120C (12 MP), MA310S (31 MP) and MA650S (65 MP), to meet a variety of measurement requirements in different applications. The most brilliant imaging colorimeter ever.

From pixels to perfection:

color measurement redefined by UPRtek Imaging Colorimeter

References

- Wuyi Ming, Shengfei Zhang, Xuewen Liu, Kun Liu, Jie Yuan, Zhuobin Xie, Peiyan Sun, Xudong Guo (2021). Survey of Mura Defect Detection in Liquid Crystal Displays Based on Machine Vision. Special Issue Liquid Crystals in China

https://www.mdpi.com/2073-4352/11/12/1444?utm_source=chatgpt.com - Rahul Awati (2022). field of view (FOV).

https://www.techtarget.com/whatis/definition/field-of-view-FOV - Li-Te Fang,1 Hsin-Chia Chen,1 I-Chieh Yin,1 Sheng-Jyh Wang,1 Chao-Hua Wen,2 Cheng-Hang Kuo3 (2006) Automatic mura detection system for liquid crystal display panels

1National Chiao Tung Univ. (Taiwan) / 2Taiwan TFT-LCD Association (Taiwan) / 3Industrial Technology Research Institute (Taiwan) https://opticalengineering.spiedigitallibrary.org/conference-proceedings-of-spie/6070/60700G/Automatic-mura-detection-system-for-liquid-crystal-display-panels/10.1117/12.650686.short?utm_source=chatgpt.com - Xie, Bin & Hu, Run & Chen, Qi & Yu, Xingjian & Wu, Dan & Wang, Kai & Luo, Xiaobing. (2015). Design of a brightness-enhancement-film-adaptive freeform lens to enhance overall performance in direct-lit light-emitting diode backlighting. Applied Optics. 54. 5542. 10.1364/AO.54.005542. https://www.researchgate.net/figure/Spatial-luminance-distribution-of-the-backlight-system-including-a-diffuser-sheet_fig11_279210355

- BenQ (2024) The Importance of Uniformity in Presenting Accurate Images on Screen.

https://www.benq.com/en-us/knowledge-center/knowledge/screen-uniformity.html - Mark Williamson. (2018). Optics for High Accuracy Machine Vision

https://www.qualitymag.com/articles/94676-optics-for-high-accuracy-machine-vision

Other Posts:

- Western Blot Imaging System: What Machine is Used for Western Blot?

- How WELL Certification Enhances Building Environments for Better Health and Well-being?

Hot Product

Handbook Series

The Flicker Handbook

Everything thing you need to know about Flicker, an insidious, potentially serious lighting artifact impacting visual safety for public places like hospitals, offices, libraries, and more...

About UPRtek

United Power Research and Technology

UPRtek (est. 2010) is a manufacturer of portable, high-precision light measurement instruments; Handheld Spectrometers, PAR meters, Spectroradiometers, Light Calibration Solutions.

UPRtek HQ, R&D and manufacturing are all based out of Taiwan, with Worldwide representation through our certified Global Resellers.

Latest Articles

Category

0 Comments