LED Manufacturing Industry

Spectrometers, Spectroradiometers, Calibration Solutions used in LED product Manufacturing

There are many variables when it comes to manufacturing LED products, which makes it difficult to maintain consistency and accuracy. But there are ways manufacturers use sophisticated measuring techniques to alleviate these problems.

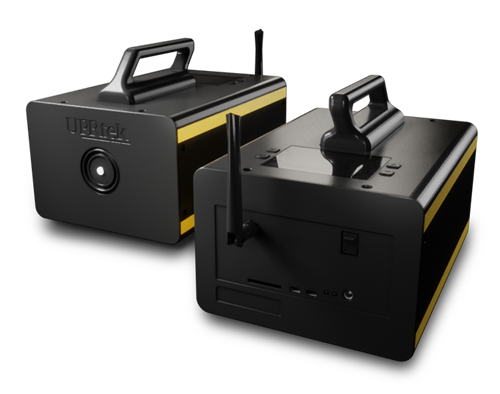

Handheld Spectrometers and Spectroradiometers

▸MK350S Premium

▸Display Panel Manufacturing

▸LED Commerce

LED Manufacturing – An inexact science.

Manufacturing an LED light on a large scale is extremely difficult. Light and color is subjective and steeped in the minutiae of quantum physics, meaning its hard to grasp, quantify and evaluate. Additonally, making an artificial LED light is an inherently imprecise undertaking; semiconductor materials, BIN ranking, color corrected temperatures are all based on ranges and estimations.

With all these variables, it’s difficult for manufacturers to measure and maintain consistency and accuracy, from product to product, from batch to batch.

So how do you control these variables?

Industry Standards help but there are many.

There are industry standards that help to unify measurement, quality and performance between products around the world. But there seems to be as many standards as there are items that need standardization. Some of the usages are determined by application, some by independent Standards Organizations, and some are governed by state agencies. In short, there are a lot of standards to consider and a good measuring device should be able to adapt.

Light measuring instruments used in manufacturing.

Measuring light to ensure color quality is paramount to LED based manufacturers. The essential equipment for measuring light is the integrating sphere. Almost all LED manufacturers or laboratory-research departments have at least one for research and testing. But it is impractical for QA/QC use on a production line – bulky, expensive, and slow.

Manufacturer inhouse RD development

One option for the manufacturer to employ inhouse RD to engineer automated QA technology directly into their production equipment (software/hardware). It is costly, labor intensive, time consuming and subject to continuing development, maintenance, and compliance with different standards.

Spectrometers used in manufacturing QA

Perhaps the most viable solution is a portable or handheld spectrometer device. First, these devices are used by manufacturers as a cost-effective way to implement QA procedures on production lines.

Second, these devices are able to adapt to different standards as dictated by the end-user application.

Third, they also can collect QA data for important management reporting and data analytics.

Fourth, they are up to 10x faster than traditional lab-level instruments. And fifth, the most important aspect is precision and accuracy – a compact light measuring device still has to deliver meticulous measurements very close to laboratory-research-level.

The UPRtek MK350S Premium has additional ad hoc manufacturing features – BIN Ranking, QA pass/fail check, interval and log testing (longevity), and compare mode. A DLL library allows UPRtek spectrometers to integrate with manufacturer inhouse RD efforts.

Spectroradiometers used in manufacturing display panels

UPRtek Spectroradiometers are used to QA-check display panels on production lines. Again, this saves manufacturers time, money and labor otherwise used for inhouse RD efforts. And even if they do employ inhouse RD efforts, a Spectroradiometer with SDKs (Software Development Kit) can also play an important role integrating its data with the RD software/hardware and assist in improving colors and even perform calibration.

Auto-calibration for Stage/Cinema LED Light Manufacturers

Achieving color accuracy during LED light manufacturing is essential for Stage Performance and Cinematic Film production. Cinema directors are very meticulous about light color quality.

However, maintaining consistency during LED light manufacturing can be a frustrating and costly endeavor. The UPRtek Color Genius product is all about auto-calibrating LED lights on the production line, alleviating those problems, and ensuring consistent color quality and behavior across all products.

UPRtek products and data analytics

Collecting data is important in manufacturing operations and has proven to be an important asset for our customers. UPRtek products all have the ability to log, store and export data.

Watch video about Chroma LED production and assembly line here.

Viable solutions for Manufacturing LEDs.

There are plenty of pitfalls to manufacturing LED lights consistently and repeatedly on a large scale. These companies are turning to specialized portable and handheld devices by UPRtek as a cost-saving, flexible QA, and quality enhancement option that can be used on production lines.

Handbook Series

The Flicker Handbook

Everything thing you need to know about Flicker, an insidious, potentially serious lighting artifact impacting visual safety for public places like hospitals, offices, libraries, and more...

About UPRtek

United Power Research and Technology

UPRtek (est. 2010) is a manufacturer of portable, high-precision light measurement instruments; Handheld Spectrometers, PAR meters, Spectroradiometers, Light Calibration Solutions.

UPRtek HQ, R&D and manufacturing are all based out of Taiwan, with Worldwide representation through our certified Global Resellers.

Latest Articles

Category