CG01 Color Genius

Lighting calibration solution for Manufacturers of Cinema and Stage LED Lights

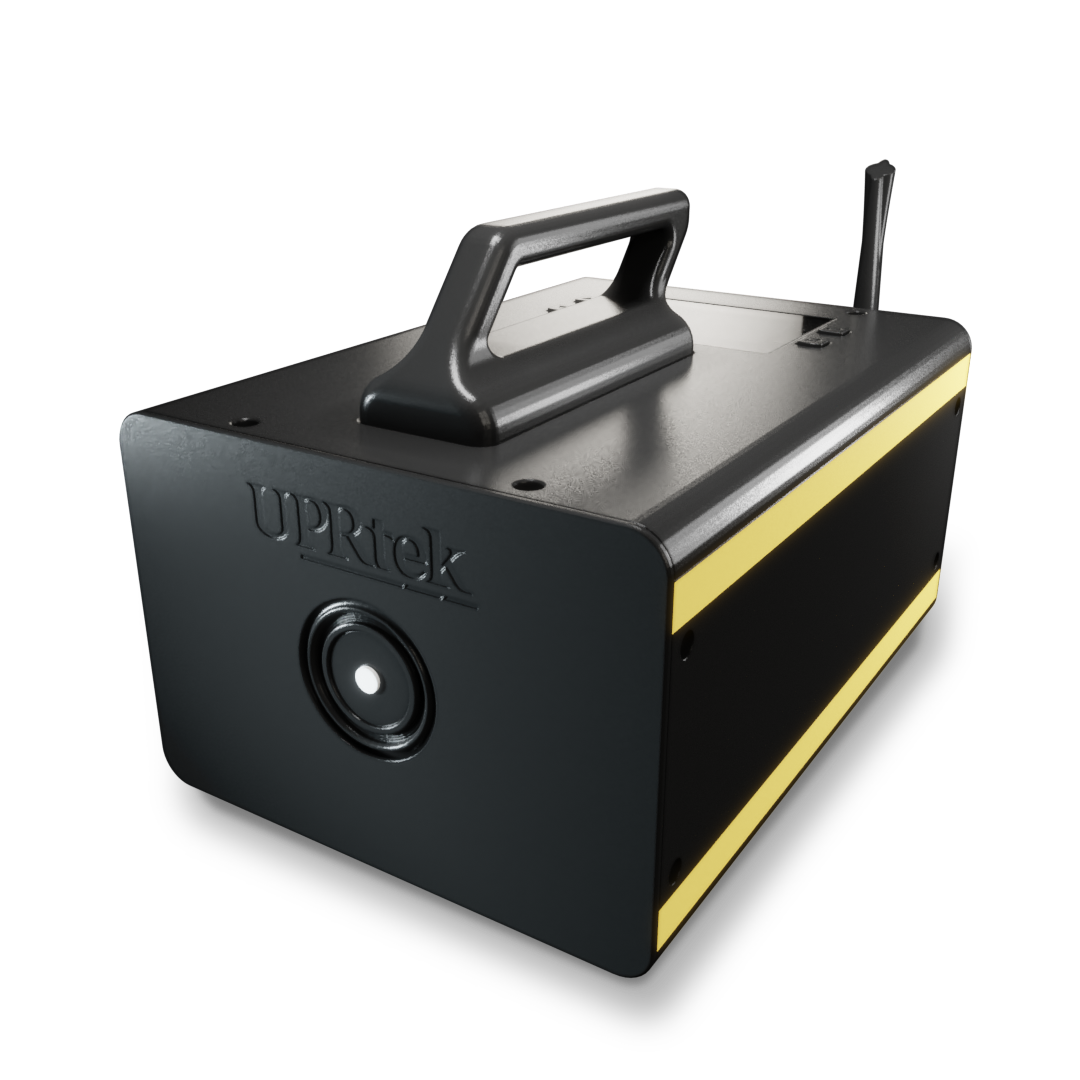

The CG01 Color Genius (lighting calibration solution) is a device that computes the corrective measures to calibrate the LED light for color consistency according to the CIE1931 reference standards.

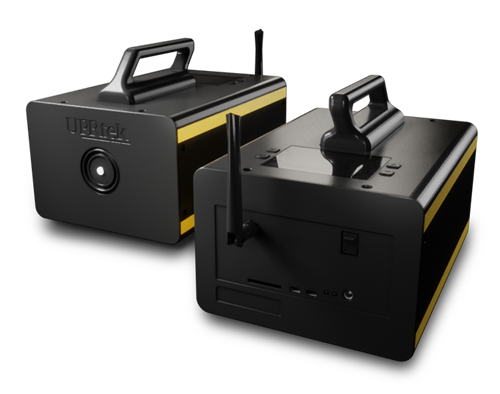

CG01 Color Genius (front and back views)

Photo by Alexander Dummer on Unsplash

CG01 Color Genius (LED Light Calibration Solution)

(click image to download 360 view)

Introduction

The portable CG01 Color Genius is used to color calibrate LED lights during the manufacturing process, to improve the consistency in color performance and behavior before shipment. It’s for manufacturers of Cinema and Stage LED Lights, which use mixed RGBW values to derive their colors. It addresses the problem of subtle color differences that lighting directors notice in LED lights when setting up for a film shoot or stage performance.

This product is designed for manufacturers of Cinema and Stage LED Lighting

Learn about Color Genius in 4 min 24 sec

Specs at-a-glance

| Specs at-a-glance | ||

|---|---|---|

| Spectrum | ||

| Sensor | CMOS | |

| Wavelength Range | 350 to 800 nm | |

| Spectral Bandwidth | About 9 nm (Half Bandwidth) | |

| Integration Time Range | 100µs to 1,000 ms | |

| Features | ||

| Mode |

| |

| Measuring Indexes |

| |

| Connection Controlling Items |

| |

| System | ||

| Display | 2.7" OLED monochrome OLED | |

| Dimensions | 260 x 150 x 140 mm(H x W x D) | |

| Weight (with Batteries) | 3,800 g ± 10 g | |

| Display languages | English / Chinese | |

The problem your Cinema LED customers are having.

Your customers are Cinema and Stage lighting crews, who have the challenge of setting up consistent color lighting throughout a performance area. Even though the lights are of the same type and make, the color performance and behavior may vary – setting the color temperature (e.g. 4000K) on one light doesn’t mean the exact same color on another – the lighting director can still notice variations.

The lighting crews will have to meticulously adjust the controls on the back of each light (e.g. RGB knobs), while someone stands afar to make sure (by sight) that they all match. It may take 1 or 2 extra hours of tedious and visually exhausting work, but it has been the only way to remedy the situation.

This variance in color between same make and model of lights is not a problem with the manufacturing. The problem is the nature of LED lighting, which is inherently an inexact science.

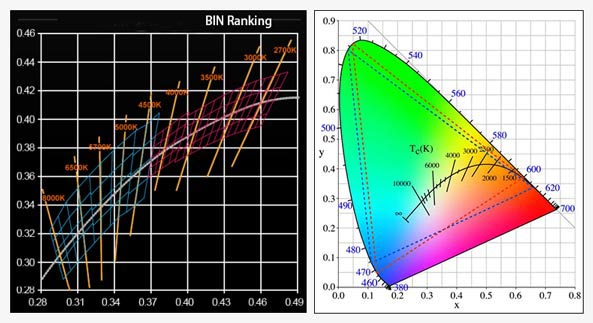

Individual LED chips are color classified (BIN rated) before being placed in light fixtures. But this classification only represents a range of color. This will also mean that the gamut areas of each light can vary. Additionally, the CCT or Correlated Color Temperature itself is only a range around the ideal Planck reference curve. It’s the ranges, the room-for-error, which is the source of the inconsistency between lights.

The problem with manufacturing a better light – time and cost

Some manufacturers go to great lengths to resolve these inconsistencies in an LED light. You can pay extra for LED emitters with tighter bin ratings (smaller color range) but it’s still a range and still subject to variance.

Brightness is also a factor in LED color accuracy. At low levels of brightness, the color fidelity becomes unstable – this has been a problem that has long plagued manufacturers and consumers alike.

Some companies will develop their own algorithms to adjust the delta values and compensate for LED variance. But the problem is that you’ll have to rewrite them for future batches whose bin ranges and gamut areas will vary again. In any case, it’s expensive, time consuming and labor intensive.

The Solution – How CG01 Color Genius works

The CG01 Color Genius is a device that measures light from an LED light and computes the corrective measures to calibrate the LED light for color consistency according to the CIE1931 reference standards.

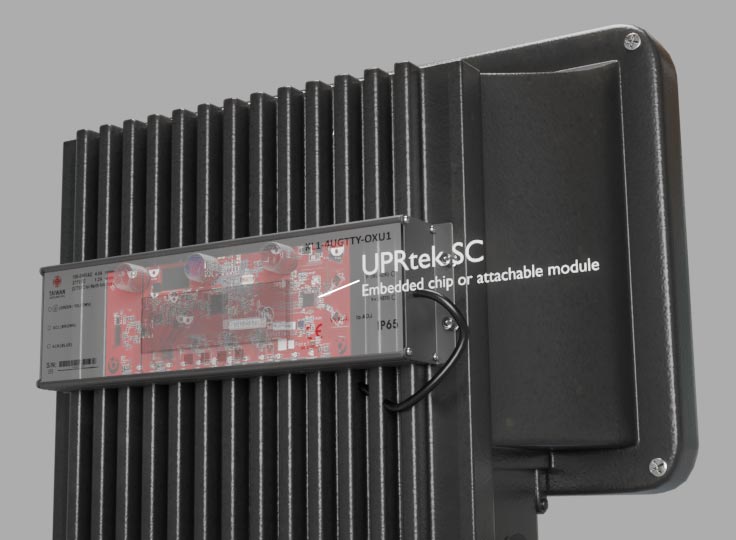

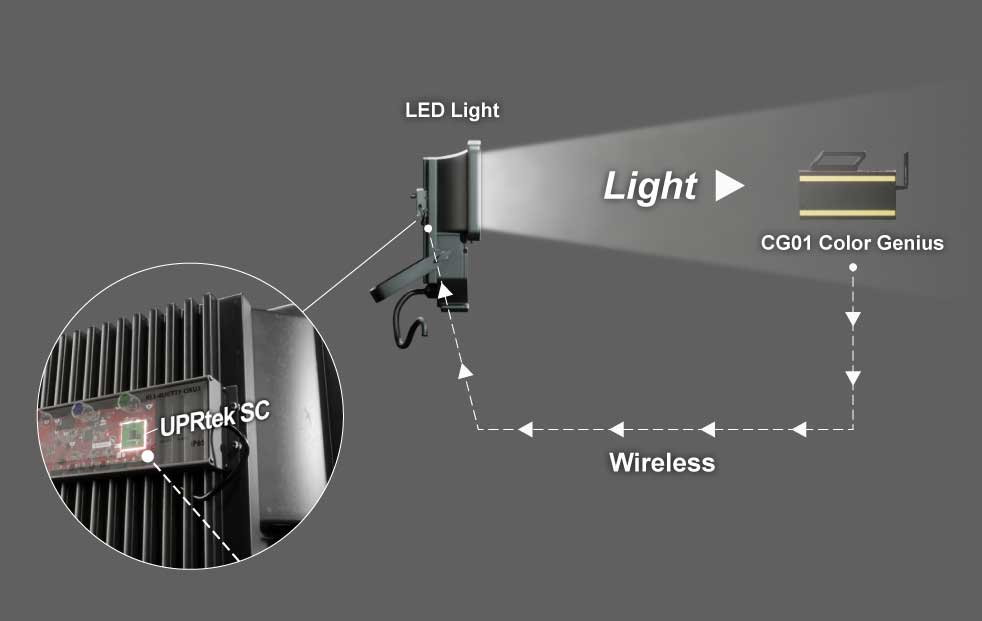

For the CG01 Color Genius to work, a UPRtek SC (Smart Color) calibration module or chip must be embedded onto the LED control module of the light fixture as a permanent component. It is used as the serial communications protocol from the SC module to your control module.

With the SC module installed, the CG01 Color Genius can now communicate with the SC module through Bluetooth wireless communications.

The Light Fixture is placed in front of the CG01 Color Genius and turned on. The CG01 analyzes the Red, Blue, Green, White spectrums individually, and at different intensities, to understand the behavior and discrepancies of the light. It then sends this data to the SC module which stores this data. The SC module can now use this information to instruct the LED light how to adjust its RGBW behavior, to align with the CIE1931 reference and Planckian locus. For a factory line, the setup and calibration is only 3 minutes per light.

The CG01 Color Genius is “Smart”

The actual working algorithms that the CG Color Genius employs is the key. In short, it takes into account the myriad of permutations of any given individual LED light, and then compute the instructions to modify that particular light’s behavior to conform to a common standard. And this also takes into account everything that factors into color; including low brightness and even gamut area variations. In addition to color, the Smart Color System improves the overall light quality (e.g. CRI optimization).

When you calibrate all your lights this way, you are establishing a baseline from a common source, the CG01 Color Genius System. So, all the lights subsequently calibrated with this product, no matter the batch, will exhibit the same color behavior, right off the production line.

CG01 Color Genius Adjustable Settings

- CCT mode: Accurate control on Planck curve. CCT: 2,500 K ~ 10,000 K.

- RGBW mode: Adjustment for intensity of each primary color.

- HSI mode: Adjustment of hue, saturation and lightness. Hue: 0 ~ 360

- CIE1931 xy mode: Output adjustment of various colors on chromaticity coordinates, during which the gamut range shall not be exceeded. x coordinate: 0.000 ~ 0.999

- Power Settings and PWM Frequency settings

Brightness: 0 ~ 100%.

G/M range: -1.00 ~ 1.00.

Red: 0 ~ 65535(16 bits)

Green: 0 ~ 65535(16 bits)

Blue: 0 ~ 65535(16 bits)

White: 0 ~ 65535(16 bits).

Saturation: 0 ~ 100%

Intensity: 0 ~ 100%

y coordinate: 0.000 ~ 0.999

Brightness: 0 ~ 100%

When your customers are happy, you are happy.

As for your customers, they simply need to turn on their lights – no more adjusting RGB knobs to match colors on 10-20 lights located high up on scaffolding. All of their lights are synced, no matter 2500K or 10000K. Happy customers.

With the CG01 Color Genius, you don’t have to spend time and labor to color correct your lights through your own R&D efforts. And with all your lights calibrated with consistent accuracy and quality, your customers will be encouraged to purchase or upgrade their lights from you in the future, because you can assure them lighting consistency with their existing lights. It’s a sure way to get return business. Happy you.

Handbook Series

The Flicker Handbook

Everything thing you need to know about Flicker, an insidious, potentially serious lighting artifact impacting visual safety for public places like hospitals, offices, libraries, and more...

About UPRtek

United Power Research and Technology

UPRtek (est. 2010) is a manufacturer of portable, high-precision light measurement instruments; Handheld Spectrometers, PAR meters, Spectroradiometers, Light Calibration Solutions.

UPRtek HQ, R&D and manufacturing are all based out of Taiwan, with Worldwide representation through our certified Global Resellers.

Latest Articles

Category